An alternator test bed is a specialized setup or facility used to evaluate and assess the performance, efficiency, and characteristics of alternators. Alternators are devices that convert mechanical energy into electrical energy in the form of alternating current (AC). Here’s an overview of an alternator test bed:

An alternator test bed is a specialized setup or facility used to evaluate and assess the performance, efficiency, and characteristics of alternators. Alternators are devices that convert mechanical energy into electrical energy in the form of alternating current (AC). Here’s an overview of an alternator test bed:

- Purpose:

- The primary purpose of an alternator test bed is to conduct comprehensive testing and analysis of alternators to ensure they meet specified performance criteria and regulatory standards.

- These tests help manufacturers, engineers, and quality control personnel validate alternator designs, optimize operating parameters, troubleshoot issues, and ensure product reliability and durability.

- Components:

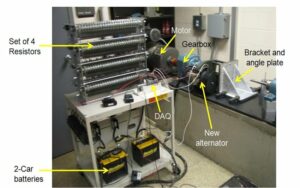

- Alternator: The alternator being tested is mounted on the test bed. It is mechanically driven by a prime mover, such as an engine or motor, to simulate real-world operating conditions.

- Load System: Test beds typically incorporate load banks or resistive loads to simulate various electrical loads that the alternator may encounter during operation.

- Measurement Instruments: Various sensors, meters, data acquisition systems, and oscilloscopes are used to measure and record parameters such as voltage, current, frequency, power output, temperature, and waveform characteristics.

- Control System: Test beds are equipped with control systems, software, and interfaces that allow operators to set test parameters, control alternator operation, adjust load conditions, and monitor performance.

- Safety Features: Safety measures such as emergency stop buttons, protective enclosures, overload protection, and interlocks are implemented to ensure operator safety and prevent damage to equipment.

- Types of Tests:

- Performance Testing: Performance tests assess the alternator’s ability to generate specified voltage and current outputs under different load conditions, including full load, part load, and no-load scenarios.

- Efficiency Testing: Efficiency tests measure the alternator’s energy efficiency by comparing the output electrical power to the input mechanical power supplied to the alternator. Efficiency is calculated as the ratio of output power to input power and is expressed as a percentage.

- Voltage Regulation Testing: Voltage regulation tests evaluate the alternator’s ability to maintain stable output voltage within specified limits as the load and speed conditions change.

- Transient Response Testing: Transient response tests examine the alternator’s ability to respond quickly and accurately to sudden changes in load or speed, ensuring stable operation under dynamic conditions.

- Temperature Rise Testing: Temperature rise tests assess the thermal performance of the alternator by monitoring temperature increases in critical components such as windings, bearings, and rectifiers during operation.

- Harmonic Distortion Testing: Harmonic distortion tests measure the quality of the alternator’s output waveform by analyzing harmonic content and distortion levels, ensuring compliance with voltage waveform standards and minimizing interference with sensitive electrical equipment.

- Benefits:

- Alternator test beds provide valuable insights into alternator performance, efficiency, and reliability, enabling manufacturers to optimize designs, improve product quality, reduce energy consumption, and meet regulatory requirements.

- They facilitate research and development efforts to innovate new alternator technologies, enhance control algorithms, and develop advanced power generation systems for diverse applications.

Alternator test beds help identify potential issues, defects, and performance limitations early in the development process, enabling corrective actions to be taken to minimize risks, warranty claims, and field failures.

Appication Of Alternator Test Bed:

- Automotive Industry: Alternator test beds are extensively used in the automotive industry for testing and validating alternators used in vehicles.

These test beds assess alternator performance under various operating conditions, such as different engine speeds, electrical loads, and temperature conditions, ensuring optimal charging system performance and reliability. - Power Generation and Energy Sector: Alternator test beds find applications in the power generation and energy sector for testing alternators used in diesel generators, gas turbines, and renewable energy systems.These test beds evaluate alternator performance, efficiency, and reliability to ensure reliable electricity generation and grid stability.

- Industrial Applications: Alternator test beds are

- utilized in various industrial applications, including construction equipment, agricultural machinery, and marine vessels, for testing and validating alternators used in these applications.These test beds assess alternator performance under harsh operating conditions, such as high vibration, temperature, and humidity, ensuring durability and reliability in industrial environments.

- Research and Development: Alternator test beds serve as valuable tools for research institutions, universities, and engineering laboratories conducting studies on alternator design, optimization, and performance enhancement.Researchers use test beds to investigate alternator characteristics, develop new control algorithms, and explore innovative alternator technologies.

- Quality Control and Certification: Alternator manufacturers use test beds for quality control and certification purposes to ensure that alternators meet industry standards and regulatory requirements.

Test beds assess alternator performance, electrical output, voltage regulation, and thermal management, ensuring compliance with specifications and standards.